HoldTight 102

Last Update

Price:

R.F.Q.

Share Product:

Detail

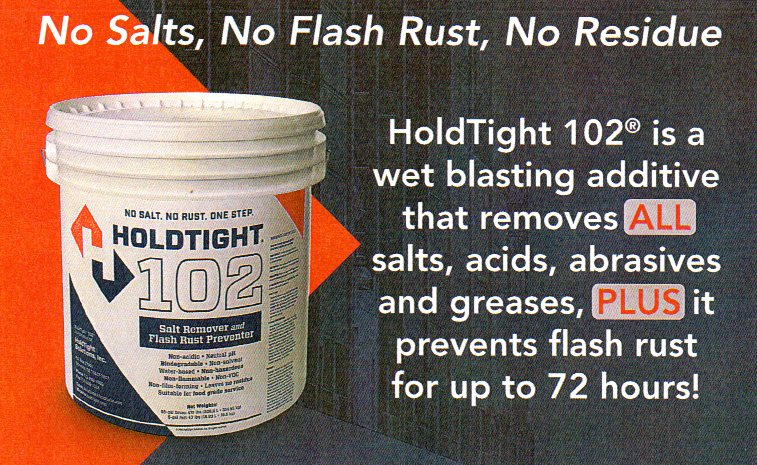

HoldTight 102

It’s no secret that coatings last longer and perform better on a clean surface.

Most cleaning methods, however, cause problems of their own:

- Dry blasting shatters the abrasive, rust and coating on the surface and leaving behind soluble salts

- Wet abrasive blasting with untreated water causes flash rust.

- Some salt removers only remove a few salts, while replacing them with other salts and leaving behind an acidic, conductive residue

With HoldTight® 102, however, there are NO contaminants, NO flash rust, and NO residue or film.

- Removes all salts, resulting in no conductivity.

- Removes abrasives and debris from the surface’s profile providing a better surface area to bond with coating.

- Leaves a clean, rust-free surface for up to 72 hours, large areas of structures can be blasted and cleaned completely before coating application, instead of having to be coated immediately after blasting every day.

HoldTight® 102 can be worked into any blasting process to achieve a totally clean surface, with zero flash-rust and zero residue left behind. HoldTight® 102 is a clear, simple additive with visible results, eliminating both natural and artificial contaminants.

At sea or on land, HoldTight® 102 is safe to use and compatible with a wide variety of surfaces, including steel, concrete, fiberglass, aluminum, composites, and more!

Any questions regarding Rust Inhibitor HoldTight 102, please send us a message or an email to enquiry@gazspec.com.

Specification

| Keyword | |

| Brand | |

| Origin | US |

Catalogue Download